Use Case 1

COBOT-Worker cooperative assembly

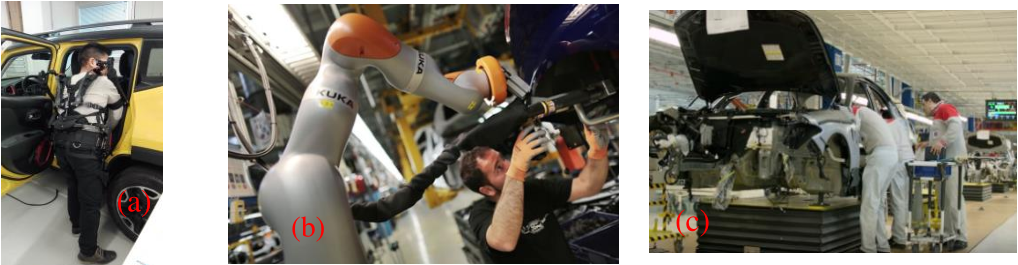

In vehicle assembly operations, the process involves workers and several tasks characterized by largely different postures, workloads, and complexity often requiring exoskeletons to reduce the biomechanical load. Additionally, it can be improved by COBOTs that either support heavy parts such as the roof or pick components and tools for the workers.

In this context, the concomitant use of exoskeletons that oversize the workers’ body, represents a possible cause of collision and damage with the other worker and possibly with the COBOT inside the cockpit. This limits the movements of the workers and slows down the process. Moreover, the assistance in keeping the position of the roof and the motions for the pick-n-delivery of components of the COBOTS, create a complex dynamical changing environment where COBOTs and workers, need to cooperate safely and efficiently.

Use Case 1 includes innovative artificial intelligence for control strategies, and the adequate sensorization COBOTs.

Demo videos

Description of SestoSenso Use-Case 1, developed at University of Genoa.

We explore how collaborative technologies can improve real work conditions, with an operator assembling the internal roof, handling flexible and bulky parts.